A Battery Management System (BMS) is a critical component of an Electric Vehicle (EV) that monitors and controls the battery pack to ensure safe, efficient, and reliable operation. The BMS is a complex system that consists of hardware and software components that work together to manage the battery’s state of charge, voltage, temperature, and overall health.

Functions of a BMS

1. Cell Balancing: Ensures that each cell in the battery pack is at the same state of charge, which helps to prolong the battery’s lifespan and prevent cell damage.

2. State of Charge (SOC) Estimation: Calculates the battery’s SOC based on factors such as voltage, current, and temperature.

3. Voltage and Current Monitoring: Continuously monitors the battery’s voltage and current to prevent overcharging or over-discharging.

4. Temperature Monitoring: Monitors the battery’s temperature to prevent overheating or overcooling, which can affect the battery’s performance and lifespan.

5. Charge and Discharge Control: Controls the flow of electrical energy into and out of the battery to prevent overcharging or over-discharging.

6. Cell Protection: Protects individual cells from damage caused by overcharging, over-discharging, or electrical faults.

7. Thermal Management: Manages the battery’s temperature to optimize performance, efficiency, and lifespan.

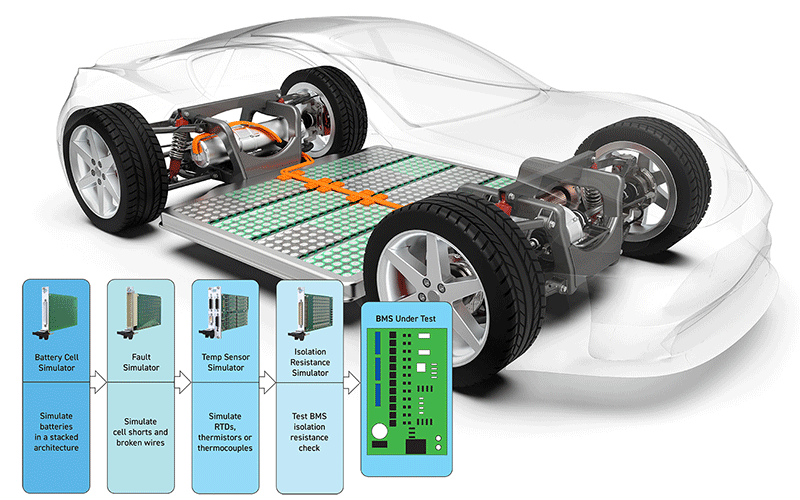

8. Fault Detection and Isolation: Detects and isolates faulty cells or modules to prevent damage to the entire battery pack.

9. Communication: Communicates with the vehicle’s onboard computer and other systems to provide data and receive commands.

Components of a BMS

1. Battery Management Unit (BMU): The brain of the BMS, responsible for processing data and making decisions.

2. Cell Supervisors: Monitor individual cells or modules and report back to the BMU.

3. Sensors: Measure voltage, current, temperature, and other parameters.

4. Power Electronics: Control the flow of electrical energy into and out of the battery.

5. Communication Interfaces: Connect the BMS to the vehicle’s onboard computer and other systems.

Types of BMS

1. Centralized BMS: A single BMU controls the entire battery pack.

2. Distributed BMS: Multiple BMUs are distributed throughout the battery pack, each controlling a subset of cells or modules.

3. Modular BMS: A combination of centralized and distributed architectures, where multiple modules are connected to a central BMU.

Challenges and Opportunities

1. Scalability: As battery packs grow in size and complexity, BMS must scale to meet the demands.

2. Cost Reduction: BMS must be cost-effective to make EVs more affordable.

3. Thermal Management: Effective thermal management is critical to optimize battery performance and lifespan.

4. Integration with Vehicle Systems: Seamless integration with vehicle systems is essential for optimal performance and safety.

5. Cybersecurity: BMS must be secure to prevent hacking and ensure the safety of the vehicle and its occupants.

Future Directions

1. Advanced Cell Chemistries: BMS must adapt to new cell chemistries and their unique characteristics.

2. Solid-State Batteries: BMS must be designed to work with solid-state batteries, which have different requirements than traditional lithium-ion batteries.

3. Autonomous Vehicles: BMS must be designed to work with autonomous vehicles, which have unique power and energy requirements.

4. Vehicle-to-Grid (V2G) Technology: BMS must be designed to support V2G technology, which enables EVs to supply energy back to the grid.

A Battery Management System (BMS) is a critical component of an Electric Vehicle (EV) that ensures safe, efficient, and reliable operation of the battery pack. The BMS must balance multiple functions, including cell balancing, state of charge estimation, voltage and current monitoring, temperature monitoring, charge and discharge control, cell protection, thermal management, fault detection and isolation, and communication. As the EV industry continues to evolve, BMS must adapt to new challenges and opportunities, including scalability, cost reduction, thermal management, integration with vehicle systems, cybersecurity, and advanced cell chemistries.