November 22, 2024

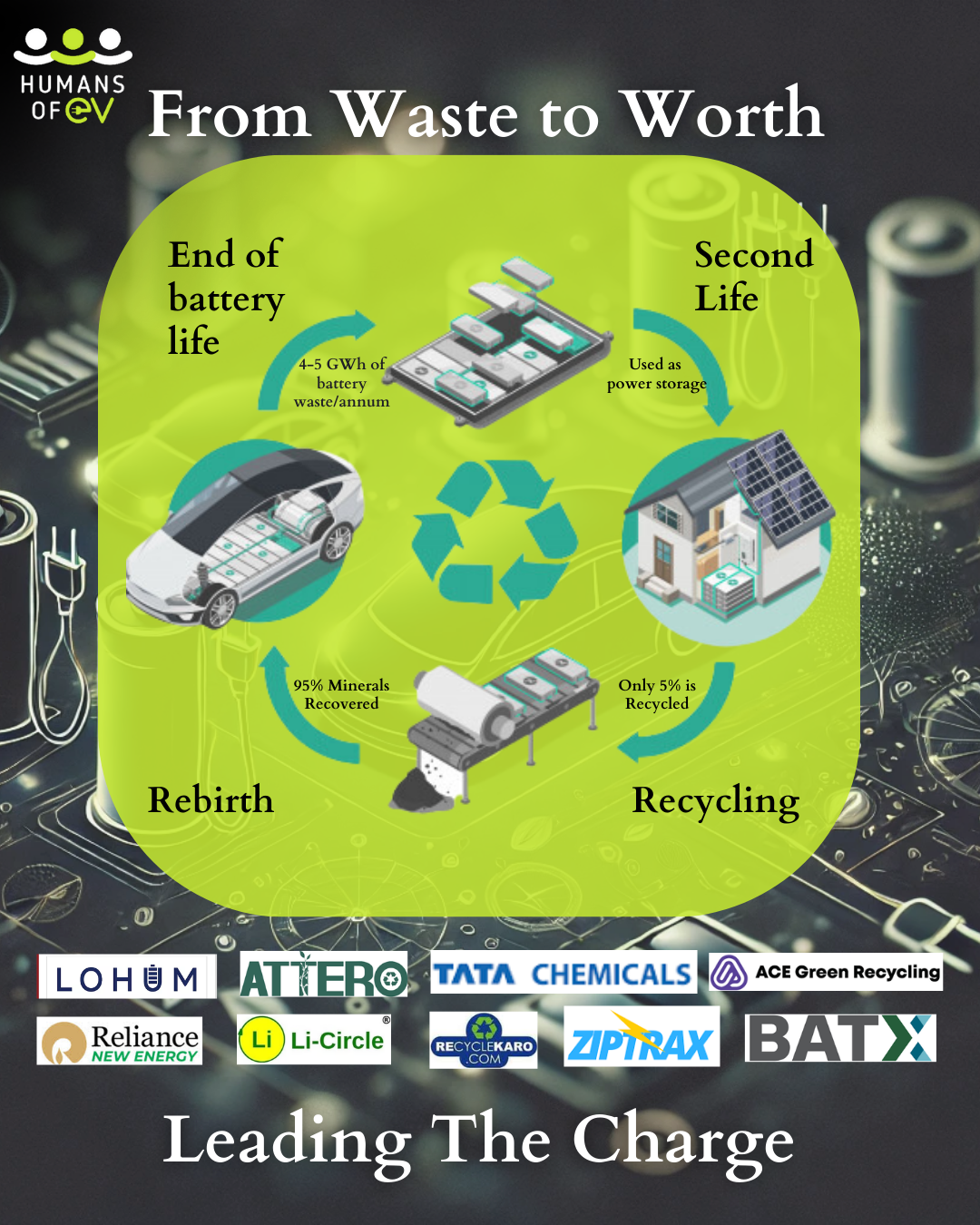

As India races towards its ambitious EV goals, a crucial question looms: What happens to EV batteries after they reach the end of their life? The answer lies in circularity—an approach that reuses, repurposes, and recycles batteries to create a sustainable lifecycle. This practice not only addresses environmental concerns but also offers immense economic and strategic value.

The Challenge

Despite the growing EV adoption, only 5% of EV batteries in India are recycled today. With inadequate recycling infrastructure and low consumer awareness, a significant volume of end-of-life batteries risks becoming hazardous waste. India also heavily relies on imports for key battery components like lithium, nickel, and cobalt, making supply chains vulnerable and costly.

The Circular Opportunity

By embracing a circular economy, India can:

- Recover up to 95% of critical minerals like lithium and cobalt through advanced recycling methods.

- Reduce dependency on imports, saving billions in foreign exchange.

- Unlock second-life applications, where used batteries are repurposed for renewable energy storage, microgrids, and more.

Future Projections

According to a Confederation of Indian Industry (CII) study, between 2022 and 2030, approximately 72 to 81 GWh of waste batteries—equivalent to 447,000 to 517,000 tons—will become available for recycling in India. This highlights the massive potential for scaling up battery repurposing and recycling in the near future.

Innovations in Action

Several companies in India are pioneering efforts to address battery end-of-life challenges:

- Lohum: Specializes in second-life applications for batteries and modular repairs, extending battery lifespans. Their innovative processes ensure maximum resource recovery while minimizing waste.

- Attero Recycling: India’s largest electronic waste recycling company, Attero reclaims valuable minerals from lithium-ion batteries, such as cobalt, lithium, and nickel, with high efficiency.

- Li-Circle: Focused on developing technologies for battery recycling, Li-Circle aims to reduce the environmental impact and reliance on imported materials.

- Reliance New Energy: Investing in state-of-the-art battery recycling and repurposing infrastructure as part of its larger commitment to renewable energy and sustainability.

- Tata Chemicals: Has initiated the recovery of cathode active materials from used lithium-ion batteries, marking a significant step in integrating recycling into its energy sciences initiatives.

- RecycleKaro: Operates India’s largest lithium-ion battery recycling facility in Palghar, Maharashtra. Known for its high efficiency, the company extracts metals like cobalt and nickel with over 90% purity.

- Ziptrax Cleantech: Uses AI-based technology to extend battery lifespans and recover valuable chemicals from used batteries. Their work supports both recycling and second-life applications.

- BatX Energies: A pioneer in Net Zero Waste and Zero Emissions technology, BatX Energies focuses on efficient recycling of lithium-ion batteries with a strong commitment to environmental sustainability.

- ACE Green Recycling: Combines cutting-edge green technology with a global footprint to offer sustainable solutions for lithium-ion battery recycling.

Solutions for a Sustainable Ecosystem

To build a successful battery circularity model, India must:

- Develop Standards for Second-Life Batteries: Establish testing and certification processes to ensure safety and performance.

- Enhance Recycling Infrastructure: Expand facilities to handle the increasing volume of end-of-life batteries.

- Support Modular Repair Systems: Encourage innovation in diagnostic tools and modular designs for cost-effective repairs.

- Create Awareness: Promote responsible disposal and the environmental benefits of recycling.

Economic and Environmental Impact

The benefits of a robust battery circularity model go far beyond sustainability:

- $2 Billion Saved Annually: Reduced import dependence.

- 300,000 Jobs Created by 2030: Employment across recycling, repurposing, and innovation sectors.

- Significant Emissions Reduction: Lower reliance on mining and fossil fuel imports.

These efforts align with India’s net-zero goals and its vision for energy independence by 2047.

The Road Ahead

India is at a crossroads. With growing EV adoption, the time to invest in battery circularity is now. By fostering collaboration between the government, industry, and innovators, India can not only solve its battery waste challenges but also establish itself as a global leader in sustainable EV solutions.